2023Year in Review

Several important events took place during the 2023 financial year: On April 3, 2023 Autoneum held its “Day 1 Celebration,” marking the successful acquisition of Borgers Automotive and welcoming some 4 500 new colleagues to the Company. The Automotive Acoustics Conference 2023, held under the scientific leadership of Autoneum and attended by 200 experts, took place in July. Two new, highly sustainable and lightweight products offering high acoustic performance – Zeta-Light and Ultra-Silent Tune – were launched. Technologies like Re-Liner and Propylat are excellent examples of a successful circular economy and represent optimal additions to the product portfolio. Autoneum’s sustainable technologies are appreciated by both customers and experts alike – the Polestar 0 project and the nomination of Re-Liner technology as a finalist for the 2023 PACE Award as well as numerous customer awards are proof of this. Behind all of these projects are our employees – they are the decisive factor for the success of our Company.

Day 1 – a new beginning for everyone

The acquisition of competitor Borgers Automotive, which was completed on April 1, 2023, marked a significant milestone for all employees. With this step, Autoneum significantly expanded its global market leadership in sustainable and lightweight acoustic and thermal management for vehicles. Borgers’ wheel arch liner and trunk liner product lines, as well as its truck business, are an ideal complement to Autoneum’s product offerings. Thanks to Autoneum’s global presence, the Borgers product portfolio will provide additional potential for profitable growth outside of Europe as well. This growth will be boosted through the active cross-selling of complementary products and technologies in all regions and customer business units worldwide. The celebration of the first shared working day, known as the “Day 1 Celebration,” was held at the former Borgers headquarters in Bocholt and was livestreamed to all locations worldwide. The celebration day represented the start of the integration process, with the goal of combining the best of both worlds to ensure a successful single entity. The organizational integration was completed by the end of 2023, as planned.

“The acquisition by Autoneum gave us a sense of a new beginning, security and, in particular, good prospects for the future.”

Industrial Engineer

“My work focuses on producing sustainable products for various types of vehicles. We’re proud when we see these vehicles on the road.”

Industrial Engineer

Polestar 0 – joint vision, unique expertise

The vision of the Polestar 0 project is as clear as it is ambitious: to create a truly climate-neutral vehicle by 2030 by creating new ways of eliminating all sources of climate emissions throughout the entire automobile industry value chain. By participating in the project, Autoneum and other industry-leading partners from suppliers to retailers will be doing their part to make this vision a reality.

With its comprehensive and long-term experience in the development of fiber-based, lightweight mono-material technologies, Autoneum is optimally suited for taking on this challenge. As part of the project, the Company will focus on reducing the greenhouse gas emissions of its polyester-based Ultra-Silent technology. With its high share of recycled materials, low carbon footprint and excellent recyclability at the end of the product life, Ultra-Silent already demonstrates excellent environmental performance.

“We are excited to join forces with other pioneers in the automotive industry and do our part to contribute to a more sustainable future for mobility.”

Head Strategy and Sustainability

“It is both the sustainability and versatility of Ultra-Silent that fascinate me. I feel proud that we can create such a variety of products from recycled material. The opportunity to further develop our technology as part of the Polestar 0 project is really motivating!”

Project Manager Customer Pre-Development

Propylat – complete vertical integration

Fiber-based, lightweight and extremely versatile – that is Autoneum’s innovative Propylat technology, made from a combination of synthetic and natural fibers with a high share of recycled materials. It reduces both exterior and interior vehicle noise. Thanks to the flexible material composition as well as the variable density and thickness of the porous material, the performance characteristics of the technology can be tailored to individual customer needs.

Propylat was originally developed by Borgers Automotive – the company that was acquired by Autoneum in April 2023 – and optimally complements the existing portfolio of environmentally-friendly textile technologies. The complete vertical integration of the technology contributes significantly to a reduction in waste. In addition, the fully recyclable variant Propylat PET fully meets the requirements for Autoneum Pure, the Company’s sustainability label.

“Propylat is a great example of Autoneum’s commitment to sustainability and operational excellence. Thanks to the full vertical integration of the technology and our vast experience with recycling processes, Propylat contributes to a further significant reduction in production waste.”

Global Product Manager Exterior

Ultra-Silent Tune – acoustic performance meets sustainability

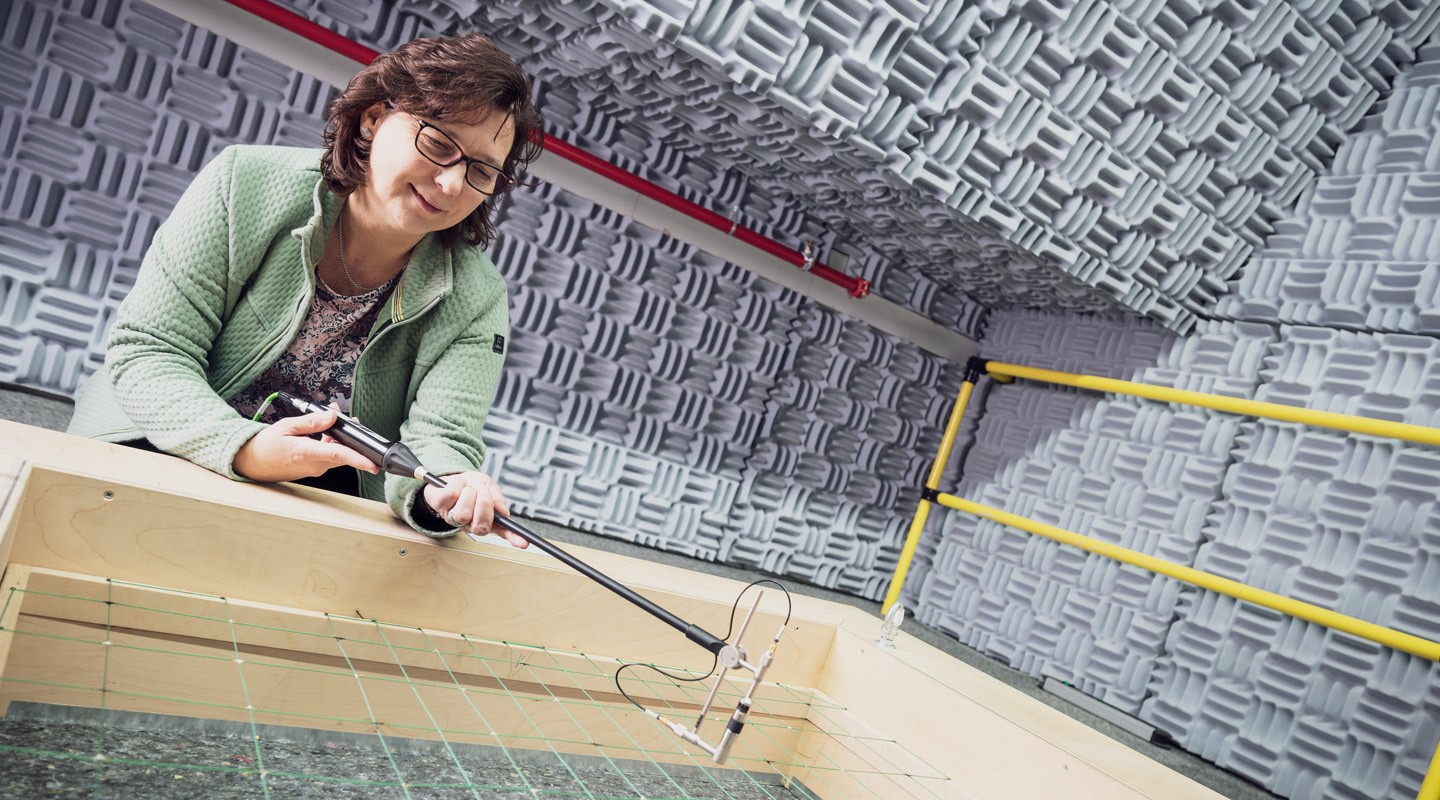

A quiet and comfortable driving experience and resource efficiency are the order of the day when it comes to developing new electric vehicle models. Ultra-Silent Tune combines optimized acoustic performance with the sustainability advantages of the highly environmentally-friendly Autoneum Ultra-Silent Pure technology. Thanks to the innovative use of chamber resonators, the lightweight technology from Autoneum for underbody shields significantly reduces the noise from automobile tires while also ensuring a quiet and comfortable driving experience in electric vehicles.

The noise-absorbing technology also meets the highest sustainability standards. In addition to a high share of recycled PET fibers, underbody shields made of Ultra-Silent Tune can be made entirely of polyester, and can thus be completely recycled at the end of the vehicle's life.

“It’s not just about developing entirely new approaches, but also about finding creative ways to make what is good even better.”

Head Development Business Unit Commercial Vehicles

“Through the innovative use of the proven concept of traditional chamber absorbers, Ultra-Silent Tune improves acoustic absorption on both sides of the components, thus significantly reducing rolling noise.”

Head NVH Tools and Methodologies

Successful turnaround of Business Group North America

Thanks to the increase in revenue and the implementation of cost-reduction measures, Autoneum’s Business Group North America posted a substantial improvement in profitability before special effects in 2023. This was supported by the non-organic growth from the Borgers acquisition and better performance thanks to the consistent implementation of the turnaround program at the North American locations. On the whole, the plants boosted their profitability considerably compared with the year before by increasing labor productivity, improving the use of materials and boosting plant efficiency.

Improvements were also made in the recycling processes, the use of chemicals and safety measures. In its media release dated January 22, 2024 Autoneum confirmed the successful turnaround in North America.

“The products manufactured in Aiken include tufted carpets, NVH and wheelhouse liners, and these are suitable for use in vehicles with different engine types. I enjoy working in the automotive industry and contributing to the creation of vehicles with my daily work.”

Machine Operator

Autoneum’s Re-Liner is a finalist for the PACE Awards 2023!

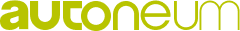

The sustainable Re-Liner technology from Autoneum uses reclaimed polymer from discarded bumpers and transforms what had been an unusable waste product into lightweight and durable wheelhouse liners. In addition to a high share of recycled material, the environmentally-friendly components require much less energy when they are produced than traditional alternatives. With Re-Liner, Autoneum uses its existing capacities on carpet extrusion lines to produce an innovative, lightweight and sturdy material, taking another important step in the direction of a more sustainable circular economy. Thanks to its Re-Liner technology for wheelhouse liners, Autoneum has been named a finalist for the PACE Awards 2023. This renowned prize recognizes excellent innovations, technological progress and business performance by automotive suppliers. The winner of the PACE Awards 2023 will be announced at the end of April 2024 at an award ceremony in Detroit, USA.

“Autoneum has recognized the untapped potential of polymer reclaimed from bumpers as a resource and given this former waste product a second life. The nomination of our Re-Liner-based wheelhouse liner for the PACE Award is proof of Autoneum’s unceasing efforts to develop both resource- and energy-efficient products and production processes.”

Vice President Product Development and Engineering

Expansion of presence in Asia

As the world’s largest automobile market, Asia is one of the most important sales regions for vehicle manufacturers and suppliers as well as a pioneer for new forms of mobility. In 2023, around 28.8 million vehicles1 were produced in China, including some 9 million new electric and hybrid vehicles2.

Autoneum served as a supplier of lightweight, sustainable components for around a quarter of the total 190 electric vehicle models produced in China on a series basis in 2023. This means that one in four electric vehicle models produced in China in 2023 includes Autoneum products. Autoneum supplies international and local vehicle manufacturers with multifunctional lightweight components for noise and thermal protection, and supports these companies in their efforts to achieve sustainable mobility.

To meet high demand, Autoneum is expanding its production capacity in China by adding a new plant in Changchun in Jilin province in 2024. This will help increase market share among European, Japanese and domestic automobile manufacturers.

With its location in Pune (Maharashtra), Autoneum is also expanding its presence in India. Autoneum already has production facilities in northern and southern India. The new production site in Pune will help Autoneum strengthen its customer proximity and tap the third of four major automobile production centers in western India.

- 1 According to S&P market forecasts "Global Light Vehicle Production Forecast" as of February 16, 2024

- 2 According to the China Passenger Car Association (CPCA) as of January 4, 2024

“The prerequisites for the development of our business are positive. My line managers recognize the work that my colleagues and I do. My team and I are motivated to continuously improve our location. Taicang received several awards in 2023, and we’re very proud of this. One award came from Volvo for our performance in terms of sustainability, and another was handed out by Jaguar Land Rover for a decade of excellent performance.”

Plant Manager Taicang

Establishment of the Business Unit Commercial Vehicles

As part of the Level Up One 6–8 strategic initiative, the new Business Unit Commercial Vehicles was established at the beginning of 2024, which sets the stage for sustainable and profitable growth. The unit includes medium and heavy trucks as well as agricultural vehicles. The goal is to use the strong customer base and Autoneum’s production capacity to expand the market presence in this segment worldwide. The Business Unit is responsible for the global commercial vehicles business development, while its financial results will be consolidated within the Business Groups. The organizational structure is focused on five main functions: sales, program, development, controlling and operations. Production facilities that manufacture products for this segment are located in Belgium, France, Germany, Poland and the Czech Republic as well as in Brazil.

“My daily work results in sound-absorbing components for truck cabins. What motivates me most is the friendly atmosphere – I feel like I'm part of a team. We have shared goals and make something that’s useful.”

Production Operator

Automotive Acoustics Conference 2023 – Hybrid edition

More than 200 participants from 19 countries, including representatives of 35 vehicle manufacturers, attended the Automotive Acoustics Conference (AAC) 2023, which was held on July 11 and 12 at the Gottlieb Duttweiler Institute, a renowned think tank near Zurich, Switzerland, and also livestreamed. The conference, which takes place every two years under the scientific leadership of Autoneum, has established itself as a global forum for engineers, developers and other experts, and it offers an ideal platform for learning about the latest developments and product innovations for acoustic management in vehicles. Last year, the AAC also presented the first opportunity to present the expanded product portfolio (thanks to the Borgers Automotive acquisition) to the public. In particular, the exhibit on the topic of sustainable vehicle acoustics, which was jointly developed just three months after the acquisition, was an impressive initial example of the teams’ successful collaboration.

“The effective team collaboration as part of the preparations for the Automotive Acoustics Conference helped us former Borgers employees to feel like we were part of ONE Autoneum. As a technical expert in acoustics, I am very pleased that the combined 80 years of experience of my acoustics team has gained more significance. We now offer customers innovative system solutions for the entire vehicle.”

Technical Expert Acoustics

Business Group Europe

Zeta-Light – low-frequency noise, high absorption

Reducing structure-borne noise, including at low frequencies, presents a particular challenge for developers and engineers working on vehicle acoustics. With Zeta-Light, Autoneum has presented a new concept that equips fiber-based liner components like carpets and inner dashes with an integrated absorption function, and thus improves acoustic performance significantly.

Thanks to the innovative use of particle dampers Zeta-Light not only dampens and absorbs airborne noise, but it also effectively reduces low-frequency body vibrations. Not only does this new damping system ensure a quiet and comfortable driving experience, it also contributes to a significant weight reduction as well as simplified parts logistics and vehicle assembly. Furthermore, because the non-woven capsules are so easy to remove, Zeta-Light is easy to recycle.

“In our department, we combine different areas of expertise to tackle challenges in sustainability, material science and acoustics, turning ideas into real-life applications. It is really rewarding when innovations like Zeta-Light take shape and lead to our joint success.”

Engineer

“The concept of Zeta-Light is as innovative as it is effective. The integrated non-woven capsules are easy to recycle and enable temperature-independent treatment of low-frequency noise at a lower weight.”

Head Core Technologies

Happy birthday, Gundernhausen, Katowice and Bursa!

Our site in Gundernhausen, Germany, was founded 60 years ago. The plant was opened on March 1, 1963 as Chemiegesellschaft Rossdorf (CHG) and specialized initially in damping materials. Six decades and two name changes later, the production site’s portfolio includes a broad range of components. In the last year alone, the approximately 280 employees produced more than 12 million high-quality vehicle components. It was here that NVH parts for a purely electric vehicle were produced for the first time last year. Even at the age of 60, Gundernhausen is still up-to-date.

Three of Autoneum’s locations celebrated an anniversary in 2023. Our plant in Katowice, Poland, celebrated its 25th anniversary. To mark this occasion, the key moments in the site’s history were presented to some 760 employees and their guests in an exhibition – from the establishment of partnerships with a number of renowned automobile manufacturers to the introduction of cutting-edge technologies to the continuous implementation of optimization and modernization processes.

The site in Bursa, Turkey, was also established 25 years ago, when the former parent company of Autoneum, Rieter, entered into a joint venture with Erkurt Holding. At the time, the plant’s 27 employees were responsible for the production of interior components for a single customer (Fiat). Today, the site has 240 employees, around nine times as many as at the time of its founding, and it supplies components to some of the biggest automobile manufacturers in Europe, Turkey and beyond. It produced some 10 million components in 2023 alone.

Ebenfalls vor einem Vierteljahrhundert gegründet wurde der Standort in Bursa, Türkei, als die damalige Muttergesellschaft von Autoneum, Rieter, ein Joint Venture mit der Erkurt Holding einging. Das Werk nahm seinerzeit mit nur 27 Mitarbeitenden die Produktion von Innenraumkomponenten für einen einzigen Kunden (Fiat) auf. Heute zählt der Standort mit 270 Mitarbeitenden rund neunmal so viele Beschäftigte und beliefert einige der grössten Autohersteller in Europa, der Türkei und darüber hinaus. Allein im Jahr 2023 wurden hier etwa 10 Millionen Bauteile produziert.