2019: Year in Review

The past year was all about innovation leadership: Whether new components for acoustics and thermal management, the world’s first online configurator for all aspects of noise protection in cars, the Automotive Acoustics Conference scientifically led by Autoneum or successful “Innovation Days” for customers – Autoneum is helping to shape the mobility of the future.

Optimal acoustics at the touch of a button

With “Acoustic Garage”, Autoneum launched in 2019

the very first online platform all around the acoustic management in vehicles. It offers users – whether customers, researchers or end consumers – a comprehensive information and product experience. With just a few mouse clicks, a customized noise protection package can be designed. Acoustic Garage is based on Autoneum’s unique simulation expertise: Software developed in-house calculates the acoustic performance of all selected component and vehicle configurations in real-time and thus secures optimum acoustic management.

Córdoba: dedicated to customer satisfaction

High product quality and delivery excellence – both are hallmarks of the Autoneum plant in Córdoba, Argentina. For these achievements, our only production facility in the land of the tango received several customer awards in 2019: Congratulations on the “Quality Award” and the “Logistic Performance Award” from Toyota as well as the recognition of being one of the “Best Argentinian Suppliers” from Iveco (CNH Industrial Group).

Greater driving range with Ultra-Silent

Autoneum expanded its product portfolio for electric vehicles in 2019 with textile battery undercovers made of Ultra-Silent. Thanks to their low weight, they contribute to a higher driving range of electric models. They also reduce vehicle sounds that become more audible due to the lack of engine noise, thus improving driving comfort. Battery undercovers made of

Ultra-Silent consist entirely of PET and act as thermal insulators. They accordingly protect the battery against cooling or heating – improved battery performance guaranteed. This product innovation will initially be used in the electric model of a German premium manufacturer.

Automotive Acoustics Conference 2019: industry leadership confirmed!

Last July, more than 220 experts discussed requirements for acoustic management associated with the mobility of the future at the Automotive Acoustics Conference in Zurich, Switzerland, which is scientifically led by Autoneum. Presentations and workshops focused on new findings related to noise protection in electric vehicles and the use of measurement systems in the pre-development of sound-reducing components.

Hybrid-Acoustics PET for sustainable noise protection

Lighter, quieter and more environmentally friendly vehicles – this is what Hybrid-Acoustics PET stands for. The newly launched technology for e-motor encapsulations particularly attenuates high-frequency sounds at the source, hence providing ideal noise protection and greater driving comfort. Components based on Hybrid-Acoustics PET are made entirely of PET that largely consists of recycled fibers and thereby meets the requirements for resource-efficient mobility solutions. Starting in spring 2020, Autoneum will be supplying numerous e-models with motor capsulations made of Hybrid-Acoustics PET.

Happy birthday Tillsonburg!

For 50 years, our plant in the Canadian city of Tillsonburg has been a byword for quiet cars. Working in a production space of more than 13 000 square meters, around 300 employees ensure that US-American vehicle models offer optimum acoustics thanks to wheelhouse inner liners, floor insulators and inner dashes from Autoneum.

Enjoy the silence with

Alpha-Liner

Automobile manufacturers around the world must comply with increasingly restrictive noise regulations for new vehicle models. Every decibel less is key. To achieve a substantial reduction, Autoneum’s multifunctional Alpha-Liner wheelhouse outer liner plays an important role. There, a thin plastic coating applied on the tire side maximizes sound absorption according to the vehicle requirements and thereby reduces tire noise. At the same time, the textile components convince with their low weight, which ensures a higher driving range. But that’s not all: The components, which are made of 100% recycled PET fibers, can be completely reclaimed and are therefore particularly sustainable.

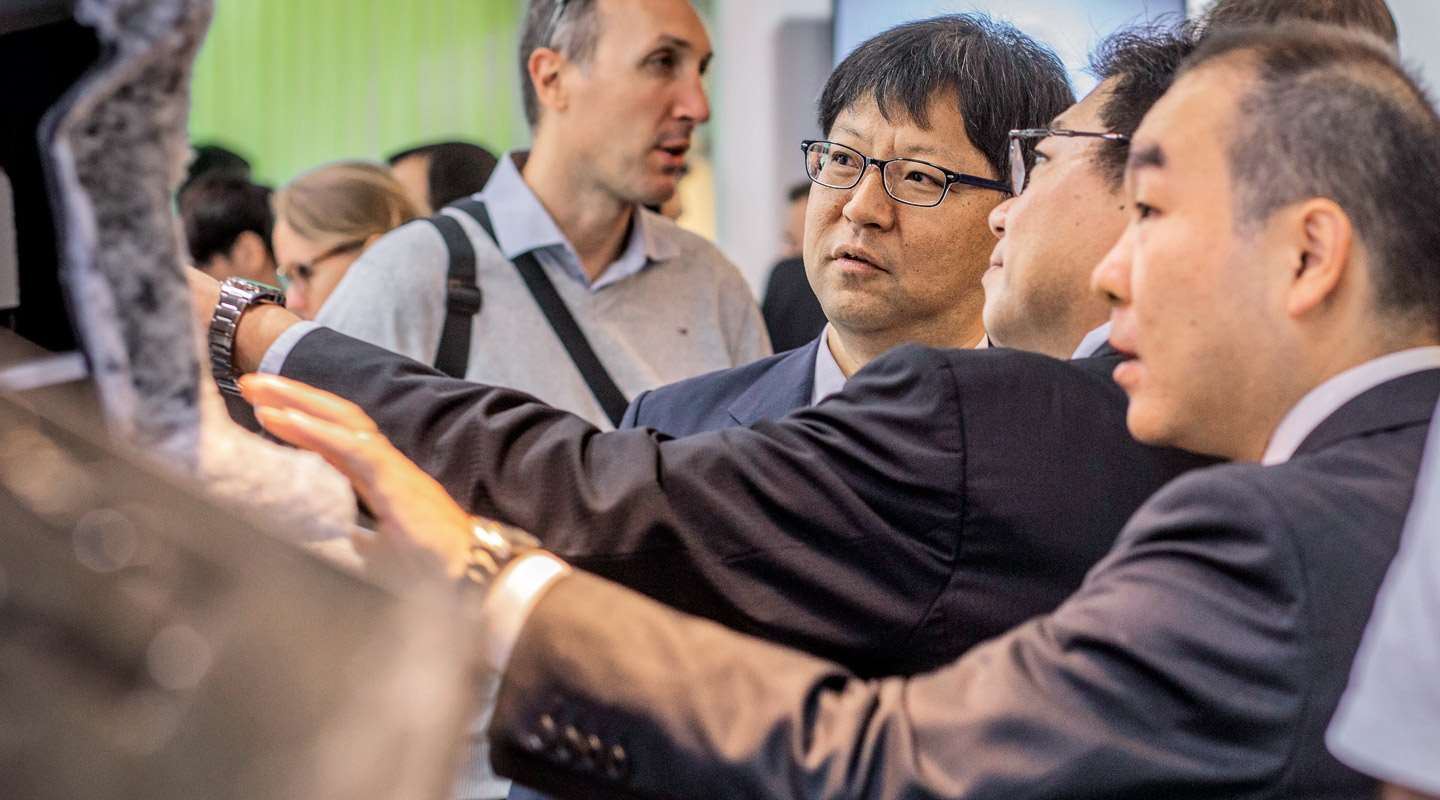

Successful “Innovation Days” in Japan

In order to show current and potential customers the extensive benefits of its product innovations, Autoneum conducts in-house exhibitions at automobile manufacturers around the world. In 2019, these “Innovation Days” took place at Toyota, Nissan and Honda in Japan, among others. Particularly sustainable innovations for use in electric vehicles were presented in the form of lightweight underbattery covers made of Ultra-Silent, along with Alpha-Liner wheelhouse outer liners.

To the top with Autoneum

Promoting innovation in the automobile industry is the basis of the long-term partnership with the leading industry accolade, the “World Car Awards”. Every year, a large number of the nominated models benefit from Autoneum’s technology leadership in acoustic and thermal management. The fully electric “I-PACE” SUV from Jaguar convinced in 2019 also due to its numerous Autoneum components and became the first model to win the “World Car of the Year”, “World Car Design of the Year” and “World Green Car” awards simultaneously.